The importance of hands-on experience.

At Applied Kinetics, we have strong theoretical engineering and analysis skills, but because we don’t build the equipment we design, clients sometimes wonder how we deal with the perceived gap between design/engineering and manufacturing. It is something that we are conscious of, and because we have little opportunity to correct design errors during manufacturing process, we make the extra effort to ensure that the designs we release to manufacturing are not a ‘work in progress’. Designs and drawings are checked thoroughly before they are released to ensure that not only are customer requirements met, but manufacturability is taken into account. Manufacturability, however, isn’t something that can just be applied at the end of the design process—it needs to be considered at every step along the way. This is something we are not afraid to get our hands dirty—literally—to achieve.

There is often a chasm between the engineering world and the manufacturing world. Many mechanical engineers have little or no hands-on experience with or personal exposure to real world manufacturing. The result is designs which show little regard for how the parts will be made, despite the increasing popularity of the term ‘design for manufacturability’. This drives up costs due to inefficient fabrication, poor use of materials, expensive manufacturing processes, and rework. Here are some examples of poor engineering practice, caused by lack of hands-on experience, that frustrate machinists, welders, and assemblers that also increase cost and cause schedule delays:

Inappropriate material selection

Engineers leave school with a good understanding of the mechanical properties of materials, and thus are quite capable of selecting materials which meet the strength and stiffness requirements for the design. What is often lacking however is an understanding of aspects like machineability, heat treating processes, corrosion properties, or friction properties. I could go on at great length on each of these topics, but suffice it to say that an inappropriate choice for the application can have significant impact not only on cost of manufacture, but on functionality and service life as well. For example, in the food processing or nuclear industries, all stainless steel construction may be required. Where mating parts must be disassembled, care must be taken to choose appropriate grades and hardness of stainless to avoid galling issues. Another simple thing that is often overlooked is material availability, and appropriate use of commonly stocked sizes. Good practical experience with material properties and selection can help avoid some of these pitfalls.

Engineers leave school with a good understanding of the mechanical properties of materials, and thus are quite capable of selecting materials which meet the strength and stiffness requirements for the design. What is often lacking however is an understanding of aspects like machineability, heat treating processes, corrosion properties, or friction properties. I could go on at great length on each of these topics, but suffice it to say that an inappropriate choice for the application can have significant impact not only on cost of manufacture, but on functionality and service life as well. For example, in the food processing or nuclear industries, all stainless steel construction may be required. Where mating parts must be disassembled, care must be taken to choose appropriate grades and hardness of stainless to avoid galling issues. Another simple thing that is often overlooked is material availability, and appropriate use of commonly stocked sizes. Good practical experience with material properties and selection can help avoid some of these pitfalls.

Excessive number of setups/tools required

Engineers without a good understanding of manufacturing methods often focus too much on the end use and functionality of the part and fail to give enough consideration to manufacturability. The result is a design which requires unnecessary setups and tool changes, which may result in a great looking part, but drives up cost and causes schedule delays. Engineers who work regularly with machine tools themselves can take these things into consideration throughout the design process, and their parts can be manufactured for a fraction of the cost with no compromises in functionality or strength.

Poor understanding of welding

While engineers are often trained in sizing welds based on strength required for the joint, other practical aspects are often overlooked. Recognizing that the heat due to welding will distort the part is important, and hence consideration needs to be given to designing the weldment to minimize this. It is also important to consider whether the components of the weldment need machining prior to welding or whether the weldment needs machining after welding. In addition, some weldments may require special welding techniques, special filler rod materials, or post-weld heat treating or normalization. Practical experience with these issues is incredibly valuable to the engineer to make appropriate design decisions, not the least of which is whether a weldment is appropriate at all!

Lack of attention to assembly sequence

At its worst, this means parts that simply cannot be assembled, but it is also a concern in terms of servicing equipment—if an entire machine needs to be disassembled in order to replace a regular wear item, it costs the customer money in downtime and increased maintenance costs. Likewise, it is important to consider the operating environment in which the equipment must be serviced. It may not be difficult to service when the machine is sitting on a bench in a well lit assembly facility, but service in the field may mean crawling under the machine in the dark while wearing cumbersome protective equipment. A little assembly or service experience goes a long way to reinforce these ideas and ensures that the designer gives them appropriate consideration.

Confusing drawings

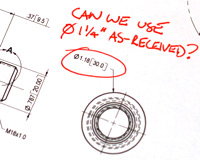

As Steven Park says in his article on drafting, “drafting is more than a skill, it is an art.” Many times a drawing can clearly depict the geometry of the finished part, but that does not necessarily translate into a drawing that is easy to interpret from a manufacturing standpoint. An understanding of how the part will be made is crucial to producing a drawing that clearly indicates how the part should be made and minimizes the chances of producing scrap or requiring rework. When a machinist produces an out of spec part, it is easy to place the blame on their shoulders, but quite often a look at the drawing will reveal that some minor changes at the drafting stage would reduce the likelihood of making such a mistake.

Poor tolerancing

Engineering judgement based on practical experience is required to select appropriate tolerances. It is easy to understand that tolerances that are too loose result in poor or inconsistent fit or performance of parts, but tolerances that are too tight can be a big problem too! Tight tolerances may result in really nice parts delivered to the customer at the end of the day, but the impact on machine time and cost can be enormous and the risk of producing scrap parts increases too.

As I’ve outlined above, practical experience with manufacturing techniques goes a long way to bridging the gap between design and manufacture. Our team of engineers has a very mechanical, hands-on mindset, and many of us do have extensive experience in machining and fabrication. We have a small prototype shop at our facility that is well equipped with machine tools, which allows us to get our hands dirty. On the surface, this allows us to offer prototyping and testing services to our clients, and to conduct experiments to support the design process. However, it goes beyond that—this ‘dirty hands’ approach means that we have a good understanding of manufacturing processes, and I believe it shows in all of our work.

This article was authored by John Duffett. Mr. Duffett has been a mechanical engineer since 2005 with experience in analysis and design. He has experience and formal training in using machine tools, is a former bicycle mechanic, and likes to tinker with cars in his spare time. He usually has some dirt under his fingernails.