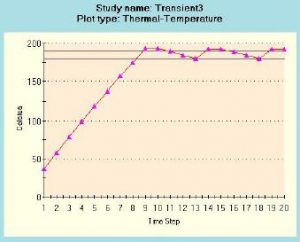

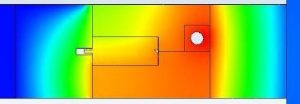

Novel heat sealer design was analyzed using thermal FEA.

Novel heat sealer design was analyzed using thermal FEA.

|

||||||||

Details: The conclusion, after Thermal FEA analysis, was that the proposed sealer design was feasible. Applied Kinetics determined that the heating element required 300W to maintain the required 185°C for sealing to occur, and that the design contained enough thermal mass to ensure a uniform seal. Applied Kinetics also concluded that only a minimum temperature drop was experienced by the sealer during operation and that the start up time of the device, if using a 300W heater, would be as low as 2 minutes. |